Horizontal Shaker Table

General Information

The Structure and Integrated Instrumentation Laboratory (SII) is equipped, within the Nantes center’s vibration bench facility, with a horizontal table mounted on hydrostatic bearings. Actuated by an electro-hydraulic jack, the table enables movements in the horizontal plane.

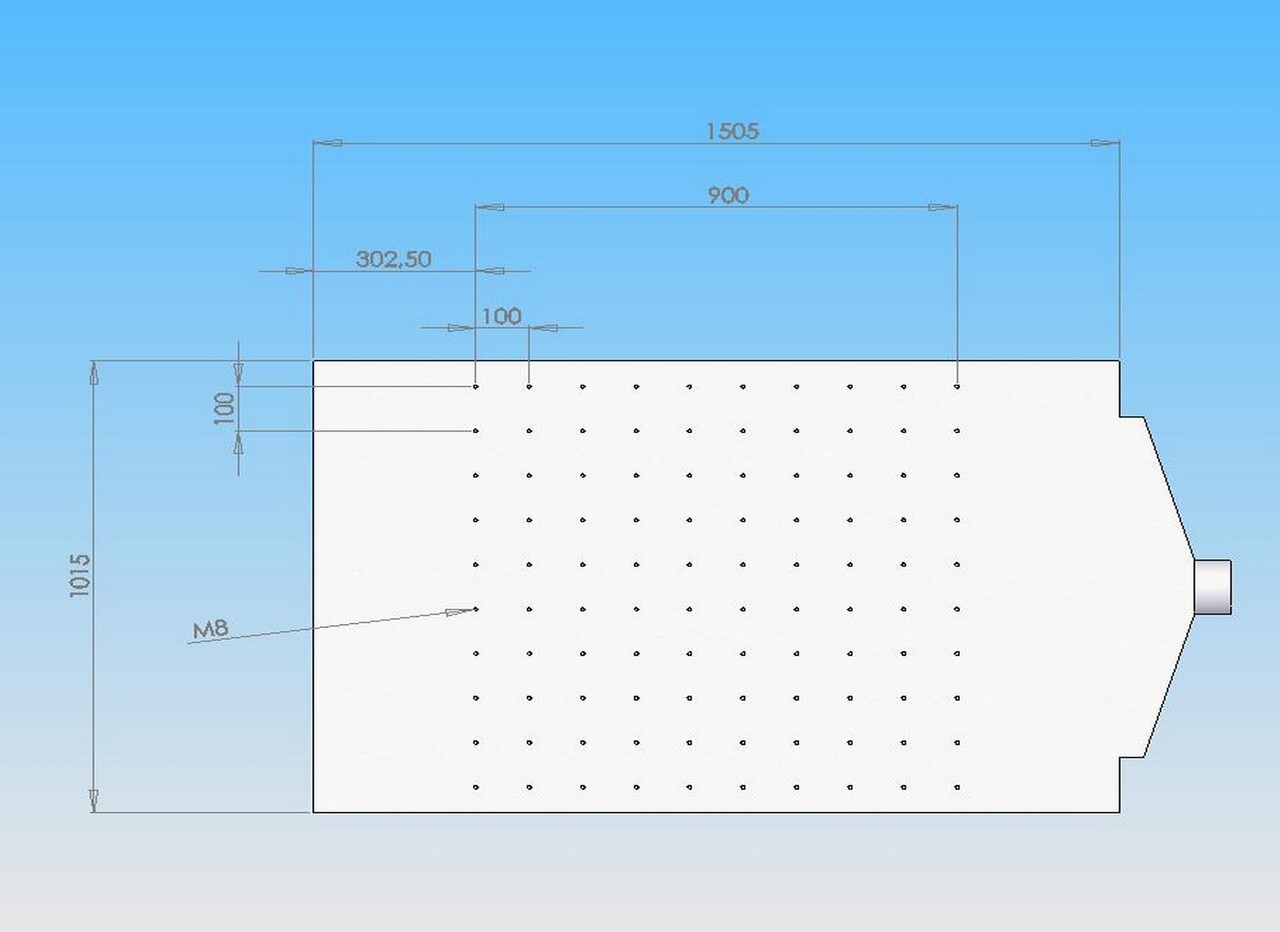

The table features an aluminum platform with a usable surface of 1 m², equipped with M8 inserts on a 100 mm pitch for securing test specimens. It moves without friction over a 40 bar oil film.

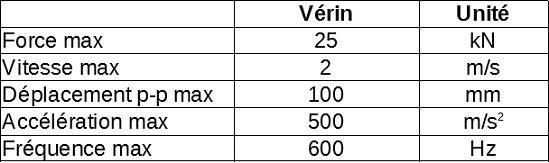

The dynamic characteristics partly depend on the capabilities of the associated jack. The moving mass without load is approximately 270 kg, allowing acceleration levels up to about 3.5 g for test specimens weighing around 300 kg. The table can also be excited with a 100 kN jack to test larger specimens. The excitation jack is mounted on a bracket fixed to the reaction mass.

The table is installed on a 6000 kg riser, with the entire assembly mounted on a 24-ton steel reaction mass resting on a sand bed, providing complete isolation from the building.

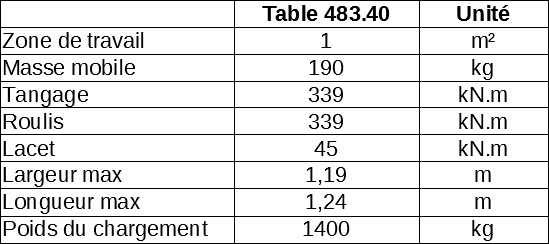

Technical Specifications (Manufacturer Data)

- This is a Team 40’’ Slip Table, model 483-40-4, with a usable surface of 1015 × 1500 mm, 50 mm thick aluminum, mounted on hydrostatic bearings.

- The table is drilled with 100 M8 inserts, spaced at 100 mm, for securing test specimens.

- There are 4 T-film bearings for guidance.

- There are 5 oil-film bearings for load support.

- The maximum operating frequency is 2000 Hz, and the resonance frequency is 750 Hz.

- Usable stroke: 100 mm

- Total table stroke: 150 mm

- Manufacturer dynamic characteristics:

- Pitch overturning moment: 339 kN·m

- Roll overturning moment: 339 kN·m

- Yaw overturning moment: 45 kN·m

- The bearing oil pressure is supplied by a hydraulic pump (LSP3) mounted on the side of the riser (42 bar, flow 3 l/min).

- The connection between the table and the actuator is made via a Team coupling rod and a connecting piece between the rod and the actuator, centered by an M24 hole.

- The table and its support are mounted on a 300 mm thick riser, raising the table and actuator axis to 505 mm above the floor.

- A bracket supports the actuator at its base. The bracket is adjustable in distance relative to the table and allows adaptation of two types of actuators: 25 kN and 100 kN.

- The maximum allowable load on the table (which must be evenly distributed) is 4000 kg.

Instrumentation

The force transmitted to the table is measured by a 25 kN load cell (sensitivity 2500 N/V).

The table displacement can be measured using the actuator’s displacement sensor (5 mm/V).

A high-sensitivity accelerometer (1 V/g) can be mounted at the end of the table.

An external gantry, decoupled from the setup, allows additional sensors to be used with the ground as a reference in the absence of vibrations.

For vibration endurance testing of specific equipment, a specialized generator, using the accelerometer, enables closed-loop control of the table to perform:

- sinusoidal sweeps with imposed displacement

- random vibrations based on a specified spectrum

- shock tests

This setup is particularly suitable for the calibration of dynamic sensors along sensitive axes located in horizontal planes.