Agilis

Agilis – Fatigue Testing on an Airport Gutter

Objectives:

Agilis commissioned Ifsttar to test the fatigue performance of a gutter made with concrete reinforced with steel fibers.

This type of gutter is intended for aircraft parking areas at airports.

The objective is to reduce or even eliminate the traditional reinforcement required in non-fiber concrete. This would allow faster casting of such gutters using a slip-forming machine, which is currently not feasible due to the congestion caused by conventional reinforcement.

The specifications require that the gutter withstand 100,000 cycles with a vertical load of 260 kN and a horizontal load of 150 kN applied over the contact area of an A3-type aircraft tire.

Loading Prototype:

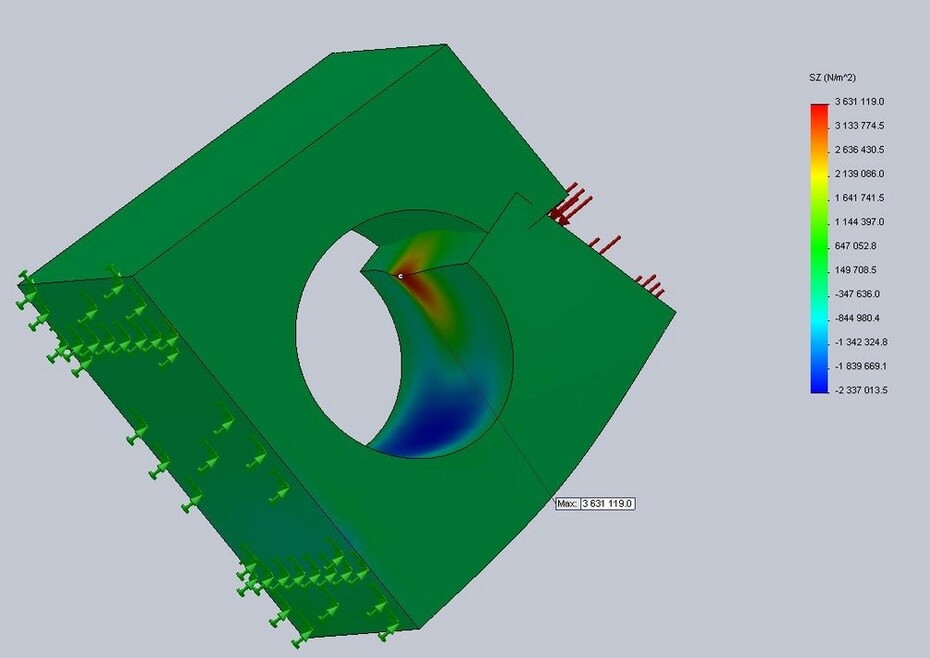

To reproduce braking forces in the laboratory (one vertical load + one horizontal load), we first designed an initial loading prototype that allows testing two zones simultaneously, positioned opposite each other.

However, this type of loading increases stress at the bottom of the gutter.

Structure Setup:

A full-scale gutter section was fabricated under real industrial conditions by Agilis in the laboratory test hall and subsequently instrumented.

The section rested on an elastomer representing the ground, and the cyclic loads were applied via two actuators installed on the test bench.

Conclusion:

The tests conducted in this study confirm the good performance of the gutter when subjected to 80,000 cycles under a constant vertical load of 260 kN and a horizontal load cycling between 10 and 150 kN, applied over an A3-type aircraft tire contact area, when the concrete and traditional reinforcement are replaced with fiber-reinforced concrete.

Furthermore, we can consider that the testing conditions adopted here are particularly severe for the following two reasons:

- The difficulty in maintaining a horizontal load of 150 kN despite adhesion of the pad representing the tire footprint to the concrete surface suggests that this load is likely overestimated in the specifications.

- The gutter had previously been subjected to 100,000 cycles under a vertical load fluctuating between 40 and 260 kN, followed by 100,000 cycles under a constant vertical load of 260 kN and horizontal load fluctuating between 10 and 100 kN, whose effects accumulate with those of the last 80,000 cycles.

For all these reasons, this project is validated in terms of gutter geometry, ground bearing capacity, as well as the loading conditions and concrete mix (dosage and fiber type).