Fondeol2

Fondeol2 – Feasibility Study of Remote Monitoring on an Offshore Wind Farm

Introduction:

An offshore wind farm is generally designed for a nominal service life of 20 years. To maintain the integrity of the wind turbines, regular inspection and maintenance must be performed. This applies to the entire wind farm, including subsea electrical distribution lines. Defining a monitoring system for a wind farm, and more specifically for wind turbine foundation structures, must take into account the variety of elements to be monitored.

Objectives:

The field of remote monitoring, or Structural Health Monitoring (SHM), uses damage identification methods to monitor the health or performance of structures across civil, mechanical, and aerospace domains. The goal is to focus on infrastructure maintenance conditions, particularly for offshore wind turbines where structures are widely dispersed. Moreover, access for personnel is more difficult than onshore, making it essential to replace systematic maintenance inspections with condition-based maintenance enabled by structural remote monitoring.

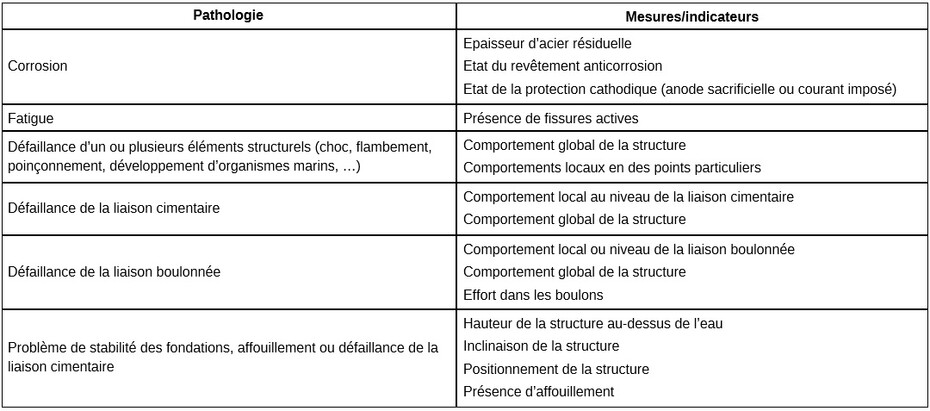

Common Pathologies and Structural Control Elements (State-of-the-Art Summary):

The definition of a measurement chain follows from documents defining the typical control points for metallic structures that can be adapted to jacket-type offshore structures. These elements are based on the state-of-the-art for potential structural pathologies and include:

- Impact from boats or floating objects

- Local buckling or punching

- Local or global settlement of the foundation (differential or overall)

- Loosening of bolted connections

- Degradation of the cementitious connection at the base

- Excessive growth of marine organisms

- Ice development for wind farms located at high latitudes (Battisti et al., 2006)

Maintenance, inspection, and monitoring operations for offshore wind turbines should focus on:

- Evolution of corrosion in different structural zones

- Condition of anti-corrosion protection systems (coatings, cathodic protection)

- Detection and characterization of cracks (active or inactive)

- Presence of local damages due to impact, local buckling, or punching

- Degradation of end connections of the jacket structure (cement base or bolted top connection)

- Local or global settlement of the structure (checking alignment or height of the exposed zone)

- Excessive growth of marine organisms

Reference Material

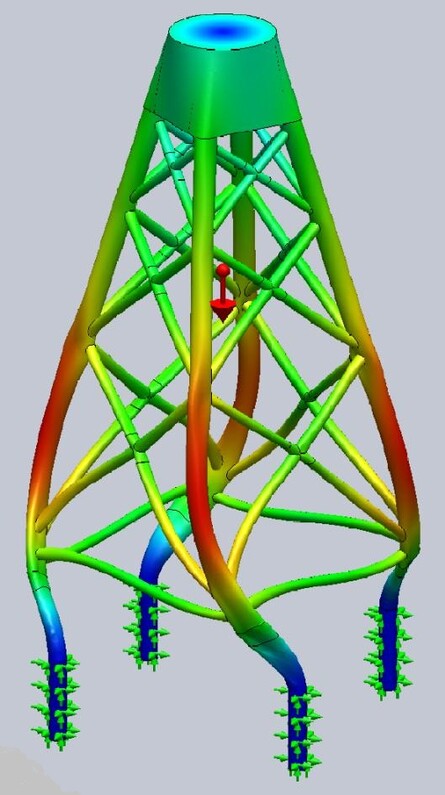

STX France, a shipbuilding company, is the French branch of STX Europe, a subsidiary of the South Korean group STX Offshore & Shipbuilding. This company is the originator of the jacket-type wind turbine support project, constructed from welded steel tubes.

With a height of 45 meters above the seabed and a weight of 420 tons, the AG1 jacket is designed to support the weight of a wind turbine over time. The study presented in this report is based on the AG1 jacket.

Modeling of Structural Pathologies

Prior to conducting numerical simulations on wind turbine foundations, a study report on the pathologies of jacket-type support structures was prepared (see: State-of-the-Art on Pathologies, Inspection, and Instrumentation of Jacket-Type Structures for Offshore Wind Turbine Supports).

This report lists scenarios likely to damage the foundations and provides their characteristics, allowing them to be simulated using finite element and numerical calculation software.

Comparison of Experimental and Classical Modal Analysis

To verify the sensitivity of the structure to structural changes, a parametric study was conducted to assess the impact on the relative variation of the structure’s natural frequencies:

STX Study on the Sensitivity of the Wind Turbine to Environmental Conditions and Structural Defects

- Sensitivity study on water depth (tide):

- 27% change in global bending modes M1, M2

- Brace failure:

- -2.8% change in global torsion mode M7 for C5+

- Sensitivity study on marine growth:

- 2.1% change in global modes M3, M4 for a thickness of 90 mm

- Sensitivity study with respect to corrosion thickness:

- 1.5% change in global modes M1, M2, M7

- Sensitivity study for the failure of a cemented connection:

- 5% change in global torsion mode M7

The study aimed to detect even small changes in modal frequencies.

Study on Vibration-Based Methods under Ambient Excitation

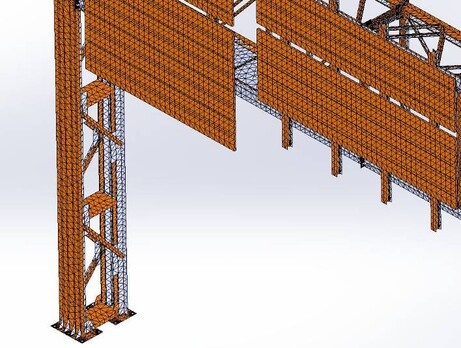

In the absence of a wind turbine model, these functions were tested on a gantry frame at IFSTTAR Nantes:

- Instrumentation of the structure using 3-axis accelerometers (Silicon Design)

- Data acquisition system of the PEGASE type, transferring data to a remote server

A sensitivity study was conducted based on a numerical model to assess the gantry’s response to structural defects.

The SSI (Stochastic Subspace Identification) method was applied.

Structural defects were introduced by adding masses to verify the sensitivity of the method.

Gantry Characteristics

The Gantry at the Nantes Site

The gantry is a metallic structure measuring 8 × 12 m, made from mechanically welded aluminum alloy profiles.

This gantry has been installed at the site for about 30 years, with each pillar anchored in a concrete foundation using 10 threaded rods, which are critical elements for the stability of the gantry.

Finite Element Model

The CAD geometric model, created with SolidWorks, was used to generate the mesh of the structure using shell elements.

The finite element mesh consists of 59,231 six-node triangular elements, with a total of 143,831 nodes.

The shell thicknesses of the structural components range from 3 to 25 mm.

The mechanical properties of the aluminum alloy are presented in the table below.

E Module d’Young (Pa) | ν Coefficient de Poisson | G Module de cisaillement (Pa) | ρ Masse volumique (kg/m^3) |

7.10^10 | 0.39 | 2.7.10^10 | 2700 |

Overall Conclusion

The Fondeol2 project highlighted the structural elements that are most critical to monitor.

Optimizing monitoring instrumentation should significantly reduce the inspection frequency of wind turbines.

Vibration-based methods under ambient excitation are currently rapidly developing for addressing these wind turbine challenges.

The use of software implementing these methods, particularly the fault detection component, allows automatic alerts to be generated at the wind farm level.

Partners:

- STX France

- École Centrale de Nantes

- IFSTTAR (Gustave Eiffel University)

- EGIS Eau