Mechanical Testing & Experiments

The mechanical workshop

The mock-ups or test-specific setups can then be manufactured, if required, in the mechanical workshop by Jean-Philippe Gourdon. The machine park, covering a wide range of manufacturing processes, notably includes a lathe, a milling machine, a shear, a press brake, and welding stations.

Mechanical experiments:

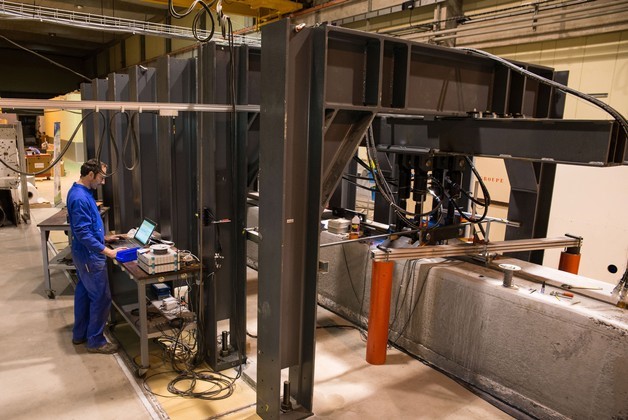

The Mechanics & Testing Group is equipped with a comprehensive testing facility known as the vibration bench.

The vibration bench consists of two testing platforms, a horizontal shaker table, and a custom excitation system dedicated to railway applications. Decoupled from the building, this setup enables a wide variety of dynamic tests for both research and industry.

The reinforced concrete platforms or test slabs measure 9 m × 4 m and 15 m × 6 m, respectively, with a height of 2.5 m. They are equipped with anchor points where jacks or test assemblies can be mounted for experiments.

The horizontal shaker table features an aluminum plate with a usable surface area of 1 m². It moves without friction on a pressurized oil film at 40 bar. Its dynamic characteristics are partly determined by the capabilities of the associated actuator. The moving mass without load is 200 kg, allowing for accelerations of up to approximately 4 g for specimens weighing 300 kg.

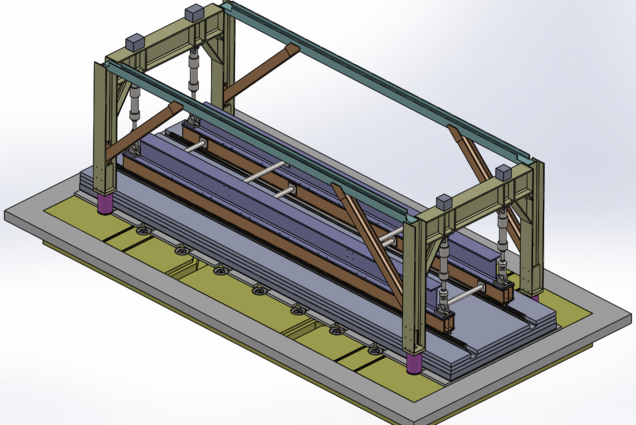

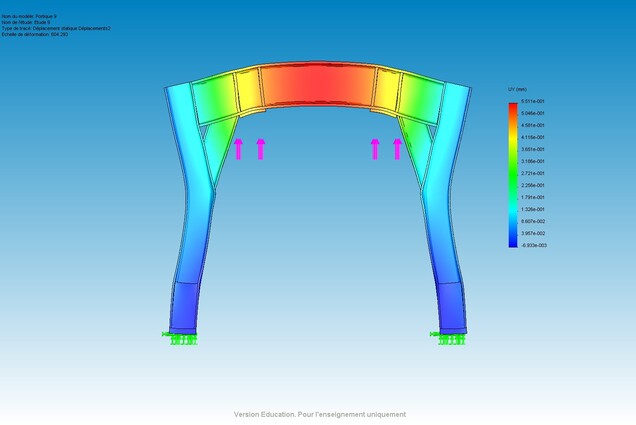

The loading system, called Sysife, built between 2016 and 2020, is designed to perform fatigue testing on mock-ups (up to full scale) of innovative railway structures.

This original linear cyclic loading system is intended to test any type of track structure (ballast, concrete, asphalt, transition zones).

Its innovative aspect lies in the cyclic loading mechanism, which allows the continuous high-speed movement of the load along the rail. This approach avoids the known drawbacks of a fixed loading system, which localizes fatigue and irreversible settlement at singular points of the tested structures.

In addition, these setups can be operated with four servo-actuators controlled via a digital console, with possible feedback control in force, displacement, velocity, and acceleration. Furthermore, we have several data acquisition systems, including dedicated sensors such as accelerometers, displacement sensors, and strain gauges.

A range of instrumented mechanical and vibration tests can be performed here by contacting Ivan Guéguen et Laurent Lebouc.